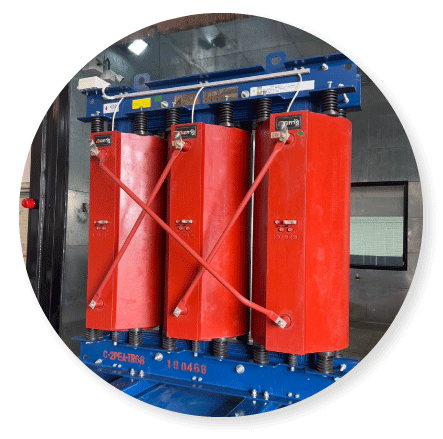

Dry Type Cast Resin (Made in Thailand)

We are the first manufacturer of Dry Type Cast Resin Transformers in the industry that uses the most modern materials and machinery today. In collaboration with international design and manufacturing experts, we are able to produce transformers that meet European standards and re highly efficient.

Our team consists of experts with extensive experience in transformers and related equipment, ready to meet the needs of both government and private sector custormers. With continuous development, we aim to be the leader in producing high-quality transformers. With advanced techonlogy and international standards that are accepted

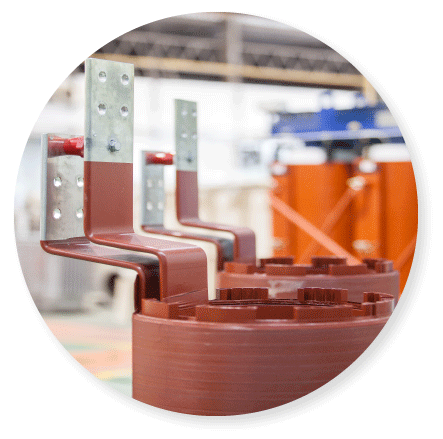

High and Low Voltage Coils are made of high quality aluminum and insulators to increase safety and durability. The wrapping process is carried out with modern European technology machinery that precisely controls the tensile force and the wrapping distance. Every step is under the supervision of experts who use specific techniques. Engineers from Europe to ensure that the coils are strong, consistent, and support efficient use.

High Voltage Coil Resin Casting

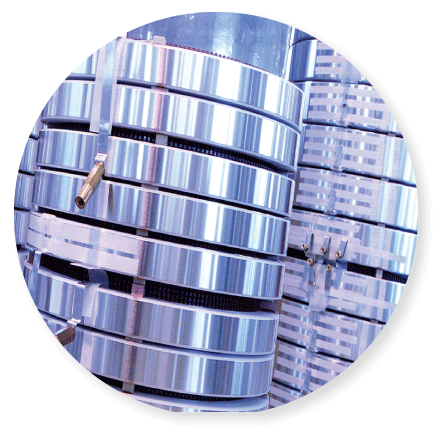

High Voltage Coils use Aluminium Foil wrapped with Class F insulation and are placed in a cleaned mold and baked to reduce humidity special resins are mixed and air bubbles are eliminated in a vacuum system with the latest rechnology machinery from Germany. Highly efficient and modern the best in the industry Resin is filled into the mold in a vacuum with precise temperature control. Avoid bubles air after that, it will be baked in an oven controlled by temperature and time to allow the resin to set completely and enhance strength. The completed coils will go through strict quality inspection before being put into use.

Low Voltage Coil Resin Plating

Low Voltage Coils use Aluminium Foil wrapped with Class F or Class H insulation and are put into the resin plating process to allow the resin to completely penetrate every layer of the coil. After plating, the coils are baked in an oven the controls the temperature and time. This process enhances the electrical strength and durability for use in a variety of environments. Low-Voltage Coils that have undergone the complete plating and baking process under go rigorous quality inspections to ensure that they meet the specified standard.

Assembly of Cast Resin Dry Type Transformer

High snd Low Voltage Coils are assembled with high quality silicon steel core with high magnetic permeability, supporting a maxinum voltage of 110% of the rated voltage. Without causing any damage to the transformer core. Increases the efficiency of magnetic flux transfer between the core legs and yokes with the Step-Lap overlay technique with core sheet coating with heatresistant insulating material and is held in place by reinforcement devices to support the coils and prevents the movement of the core plate during transportation and reduces vibration during use. This process uses a special technique by expert engineers from Europe to ensure the highest quality and reliability.